Lean Management

Streamline Your Operations, Maximize Your Potential.

Lean Management

In today's fast-paced business environment, efficiency is key to staying competitive. At Stat Modeller, we specialize in Lean Management training and consulting, empowering organizations to optimize their processes, reduce waste, and drive continuous improvement.

Why Choose Lean?

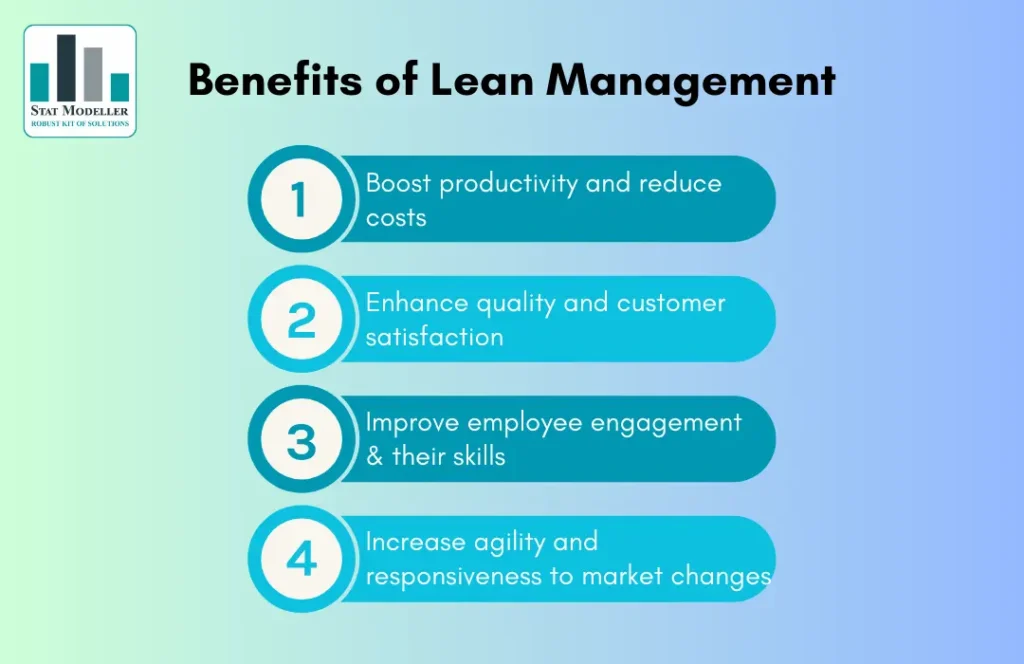

Lean principles have revolutionized industries worldwide, from manufacturing to healthcare and beyond. By focusing on value creation and waste elimination, Lean Management helps you:

Our Approach

We don't believe in one-size-fits-all solutions. Our expert consultants work closely with your team to:

Diagnostic Assessment

We start by thoroughly analyzing your current operations, identifying bottlenecks, inefficiencies, and areas ripe for improvement.

Strategy Development

Based on our findings, we create a customized Lean implementation strategy tailored to your unique challenges and goals.

Team Training

We provide hands-on training to your staff, equipping them with essential Lean tools and methodologies to drive change from within.

Implementation Support

Our consultants guide you through the transformation process, offering expert advice and helping you overcome obstacles as they arise.

Continuous Improvement

We help establish systems for ongoing monitoring and refinement, ensuring that Lean principles become ingrained in your organizational culture for sustained success.

This approach ensures a holistic transformation that not only addresses immediate inefficiencies but also builds a foundation for long-term, continuous improvement.

Training Programs

Our dynamic Lean Management training programs cater to all levels of your organization:

Ideal for beginners, this workshop introduces core Lean concepts and tools. Participants learn to identify waste, map value streams, and implement basic improvement techniques.

Usually, it is planned for 2-days, however, it can be customized as per the need.

Dive deep into the art of visualizing workflows. Learn to create current and future state maps, identify non-value-added activities, and design optimized processes.

Usually, it is planned for 3-days, however, it can be customized as per the need.

Master the skills to lead rapid improvement events. Participants learn to plan, execute, and follow up on Kaizen initiatives, driving quick wins and cultural change.

Combine Lean principles with Six Sigma methodologies. This program equips participants with advanced problem-solving tools and project management skills to tackle complex challenges.

Consulting Services

From targeted improvements to full-scale Lean transformations, our consulting services are designed to meet your specific needs:

Our experts conduct a comprehensive analysis of your operations, identifying inefficiencies and improvement opportunities. We provide a detailed report with prioritized recommendations and potential ROI estimates.

We develop a tailored strategy for your Lean journey, considering your unique challenges, goals, and organizational culture. This roadmap outlines key initiatives, timelines, and resource requirements for a successful transformation.

We guide your team through the implementation of essential Lean tools such as 5S, Visual Management, Standard Work, and Kanban. Our hands-on approach ensures these tools are effectively integrated into your daily operations.

Our consultants work with you to streamline your core processes, eliminating waste and enhancing value creation. We help redesign workflows, optimize resource allocation, and improve cross-functional collaboration.

We assist in fostering a culture of continuous improvement throughout your organization. This includes leadership coaching, employee engagement strategies, and establishing sustainable improvement systems.

We help you develop and implement meaningful performance indicators aligned with Lean principles, enabling data-driven decision-making and progress tracking.

For specific improvement initiatives, we offer project management support to ensure successful execution, from planning and implementation to monitoring and sustaining results.